More About Quality…

Quality drives all aspects of our organization, from our Mission Statement to our Maintenance Department to our In-House Lab.

Our Quality Department consists of our Production Assurance Manager, our Quality Engineers and multiple Inspectors for each shift. In addition to this, we have full-time maintenance and process control departments that contribute directly to our award-winning quality program.

We have two full-time maintenance technicians who operate our Preventative Maintenance program, supported by a substantial inventory of spare pumps, valves and other critical spare components to minimize downtime. This means your parts will be completed on schedule all the time.

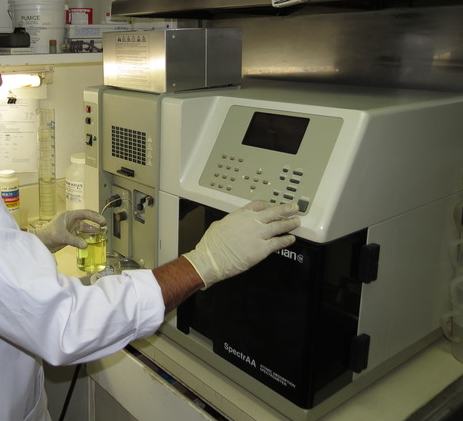

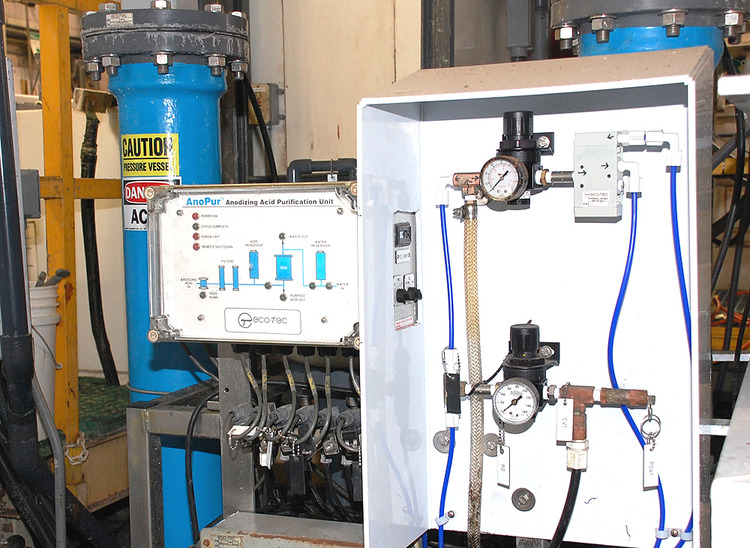

We understand that solution control is the heart of process control. Timely chemical analysis, accurate additions, and regular bath maintenance are at the foundation of our Quality program. Our on-site chemistry laboratory is equipped for precision volumetric analysis. Our investment in digital burettes is just one example of our attention to detail. Precise readings of titrant usage enable us to accurately measure the concentration of critical chemicals in our processing baths. We also recognize the damaging effects of impurities in solution. We have invested in Eco-Tec systems for continuous removal of dissolved aluminum and other impurities from our anodizing baths.

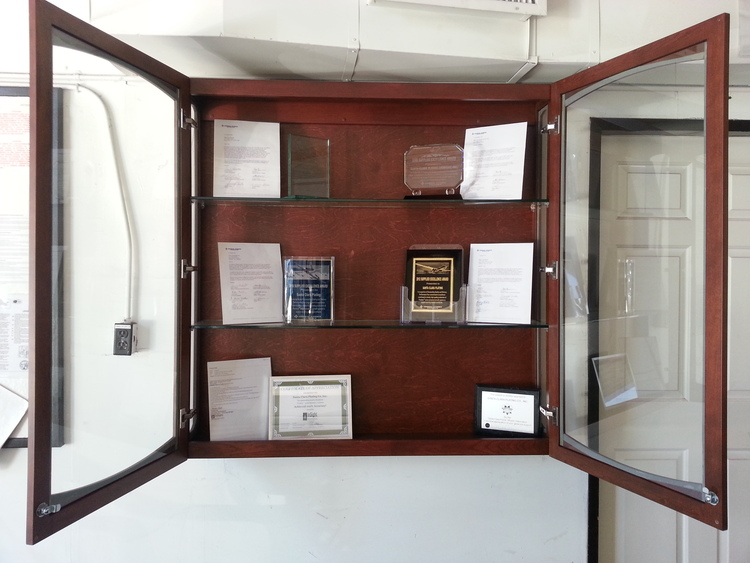

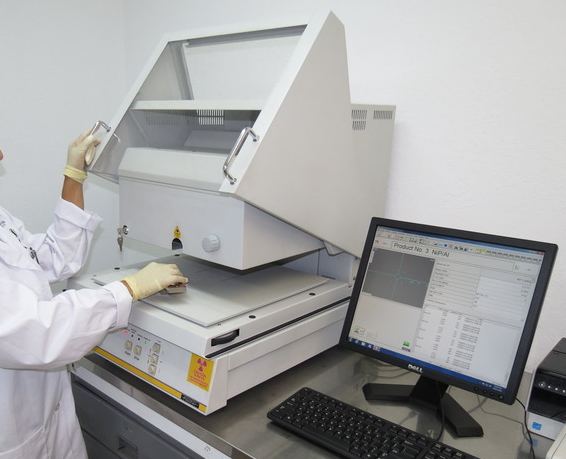

Test equipment is calibrated regularly to maintain quality baselines and includes: Atomic Absorption spectrophotometer, X-Ray flourescence tester, Fischerscope MMS eddy current tester, profilometers, digital burettes, pH meters, flow meters, calipers, micrometers, part count scales, and temperature controllers. Additionally, some process validation testing is beyond the capabilities of our in-house lab. To ensure quality, our process control department utilizes outside certified labs monthly for: Salt Spray, Anodic Coating Weight, Abrasion Resistance, Wet Tape Adhesion, Electrical Resistance, Destructive Coating Thickness, Coating Hardness, and Hydrogen Embrittlement Relief Destructive testing. Our investment in quality verification and validation is substantial and demonstrates our commitment to quality.

Old quality-think suggests that you can inspect quality into the product. More modern quality-think says you must push the defects back upstream and PREVENT them rather than simply DETECTING them. That’s what our QEs, first article procedure, bimonthly training program, and all our testing is all about… PREVENTING quality problems!